A method for fabricating powders with a core-shell structure was proposed at the TSC SB RAS

Researchers from the Tomsk Scientific Center SB RAS fabricated core(Al)-shell(Y/Dy) particles by electron beam treatment of Al powder. Such powders containing rare earth metals will make it possible to produce highly oxidation resistant gas burners using self-propagating high-temperature synthesis. The research was funded by Russian Science Foundation (No. 21-79-10445). The results are reported in

Materials Today Communications

.

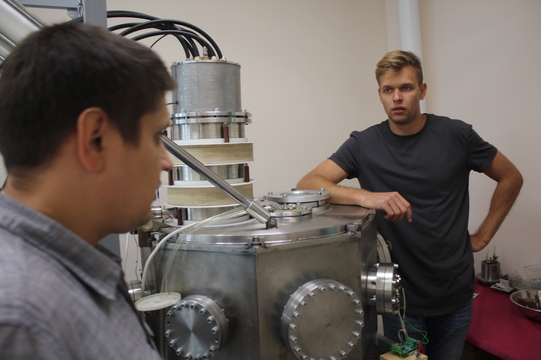

– We proposed to fabricate aluminum powders with a “core-shell” structure using an electron beam treatment and magnetron sputtering. Its novelty is in treating every microscopic object, a powder particle, rather than ready products. The process consists of two stages. First, the desired film is deposited by magnetron sputtering and treated with electron beams. Then, the core (aluminum powder) is fused with a shell of rare earth metals, – explains Evgeniy Yakovlev, researcher at the Laboratory of Advanced Technologies.

Particles with a core-shell structure are used in the field of catalysis, optics, hydrogen energy and medicine. Their use can significantly enhance the material properties and prolong the product lifetime. In this case, one can use different materials to fabricate the core and the shell of the particle. To solve problems associated with self-propagating high-temperature synthesis, with the help of which various products can be manufactured in a combustion wave, we took industrial aluminum powders for the particle cores, and rare earth metals were used for their shells.

Researchers were interested in producing powders with specific concentrations of rare earth metals and uniform distribution of yttrium (or dysprosium) throughout the initial mixture of powders. Gas burners produced using such powder will be characterized by better resistance to high-temperature oxidation in a combustion wave only if these conditions are met.

– To solve these problems, a powder holder system, providing rotary agitation and shaking of powder, was used to guarantee the uniform processing of each particle, thereby preventing them from sticking together and ensuring uniform coverage of all powder particles, – says junior researcher Evgeniy Pesterev.

The team of authors (Evgeniy Yakovlev, Vsevolod Petrov, Evgeniy Pesterev and Anatoly Maznoy) plans to continue the research in several aspects: studying the properties of gas burners produced by the self-propagating high-temperature method from powders modified using this new method, as well as finding optimal modes for fabricating powders from various metals for other applications.