Tomsk’s scientists implement an integrated approach to producing polymer coatings

Scientists from IHCE (SB RAS), Tomsk State University, and TSC (SB RAS) have laid the foundations for the synthesis of different polymer coatings with unique properties using a low-pressure glow discharge. Such polymers are in demand in medicine, mechanical engineering, and as protective coatings exploited in space and in the harsh conditions of the Arctic. These results were reported in the high-ranking journal

Vacuum

.

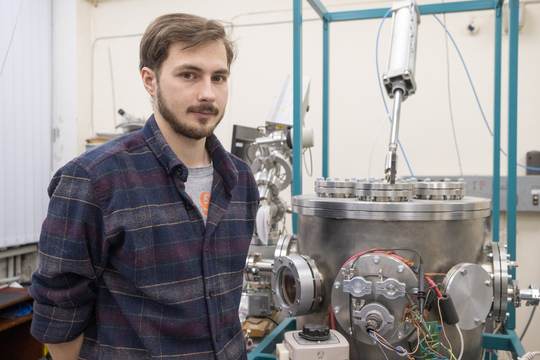

– Polymers are substances consisting of long macromolecules, where atoms are connected to each other through covalent bonds. There are natural polymers, such as the well-known cellulose or proteins. There are also synthetic polymers, for example, polyethylene or polyvinyl chloride, – says one of the co-authors of the article, graduate student Daniil Zuza. – As a rule, the synthesis of polymers is initiated by a chemical reaction between a monomer and other substances. Currently, an urgent direction is plasma chemical synthesis of polymers, which makes it possible to produce polymer coatings by activating monomer molecules in a glow discharge.

The young scientist says that the advantages of plasma chemical synthesis include the ability to produce polymers from a variety of organic or organometallic chemicals, including those that cannot be polymerized using the traditional approach, and polymer coatings in a relatively short time in one step and without using solvents.

In plasma, energy is transferred from the plasma particles to the vaporized monomer molecules and activates the molecules. As a result, highly reactive particles are formed, which are deposited on the surface and form a coating. These polymer coatings have unique properties that can be “tuned” by varying different parameters of the plasma chemical reactor.

The scientific team, which includes scientists from three institutions, deals with the topic in an integrated way, studying the fundamentals of the processes leading to plasma polymerization, designing equipment, and developing modern methods for producing polymer coatings. The result of research supported by a grant from the Russian Foundation for Basic Research in 2019 was the manufacturing of a prototype unit for applying polymer coatings using glow discharge at the Institute of High Current Electronics of the Siberian Branch of the Russian Academy of Sciences.

A special feature of the unit is that the monomer is activated in a limited volume of the plasma chemical reactor, and the reactive particles are deposited on the surface of the material in the vacuum chamber. In this way, polymers are formed without plasma exposure to the material, which makes it possible to coat products that are sensitive to such exposure. In addition, thanks to this approach, the size of the material to be processed can be large and limited only by the size of the vacuum chamber and not the electrode system.

Daniil explains that plasma chemical deposition of polymer coatings is a complex, multifactorial process, which is influenced by many parameters that are difficult to describe. Therefore, it is necessary to systematically identify empirical facts that contribute to the further development of the method.

A scientific team from the Laboratory of Vacuum Electronics and Low-Temperature Plasma (IHCE SB RAS), the Center for Research in Materials and Technologies (TSU, Chemistry Department) and the Laboratory of Advanced Technologies (Tomsk Scientific Center of SB RAS) studies the plasma chemical synthesis of polymers and the influence of parameters (composition of gas-vapor mixture, mixture flow rate, nature of substrate, glow discharge parameters, system pressure) on the polymer coating yield, its chemical composition and, therefore, on its physical and chemical properties.

The scientists were able to identify the plasma-chemical reactor modes leading to the most effective plasma polymerization of hexamethyldisiloxane to form polymethylsiloxane polymers, which have high dielectric strength, thermal stability, resistance to corrosive media and high adhesion to metallic materials.

Further development of the plasma-chemical synthesis of polymer coatings will provide the basis for modern technologies for producing materials with required properties for medicine, mechanical engineering, the food industry, and the aerospace industry.